Mobile Materials Technology app for iPhone and iPad

Developer: Trinity Bridge Digital

First release : 01 Jun 2016

App size: 75.96 Mb

DESCRIPTION

Be more effective in inspections and turnarounds with a smart tool that puts industry codes, calculations and expert advice in the palm of your hand. MTech helps you become an expert at evaluating damage mechanisms within minutes of logging in.

Designed by well-known industry experts, this patent-pending technology improves equipment reliability and inspection planning by identifying degradation mechanisms that can cause equipment to fail and calculating damage/corrosion rates according to the latest editions of API RP 571 and API RP 581 methodologies.

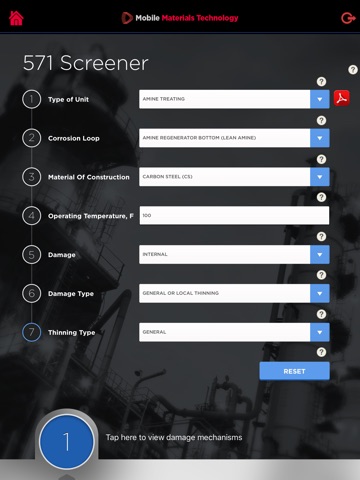

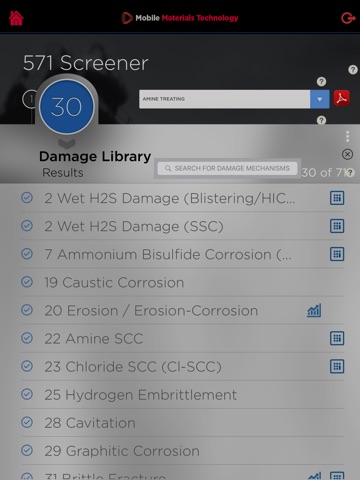

MTech puts the information you need to identify and evaluate damage at your fingertips. It simplifies the process of damage screening by asking a set of questions that define one or more likely damage mechanisms. Once the damage mechanism(s) is identified, the technology calculates probable corrosion rates according to industry codes and standards. You can check your conclusions by tapping on a Damage Library that includes extensive reference information and photos of the most common types of damage. Inspection and monitoring recommendations for each type of damage are included as well.

With MTech, you can confirm what you know and research what you suspect – be confident you made the right decision in the field, and have the information at your fingertips to back it up in meetings and RBI reviews.

FEATURES

Damage Screener smart tool for 71 damage mechanisms based on industry codes

A set of simplified PFDs (process flow diagrams) and defined corrosion loops making it easier to visualize where damage may occur in typical refinery units

An extensive Damage Library reference for each type of damage

Extensive damage mechanism photo library

Damage monitoring and inspection recommendations

Calculations to determine damage susceptibility based on industry recommended practices

USES

Turnaround planning & management

Screen and review equipment and expected damage while preparing for a turnaround.

Screen and review damage potential for specific equipment coming up for inspection to identify what to look for before the inspection is conducted.

Identify the morphology of the damage that may occur.

Explain NDE methods and figure out which method works best.

Educate less experienced personnel with examples of damage before the inspection.

Field evaluations

Evaluate and determine the potential causes of unexpected damage.

Evaluate and recommend materials of construction uses at shop or other locations.

Evaluate possible damage and determine additional information required to calculate a damage susceptibility.

Calculate expected corrosion rates or damage susceptibilities to demonstrate increasing resistance to damage by various materials at different operating conditions.

Meeting assessments

Evaluate material options and solutions and calculate the damage rate of possible material of construction solutions to damaged equipment.Evaluate expected types of damage for a new material of construction that may resolve one potential damage problem but introduce another.

Evaluate opportunities for modifying operating conditions to determine if materials are acceptable in new operating conditions.

Check the easily assessable and extensive reference information in meetings for answers that would otherwise require resolution at a later date.

RBI reviews/incident investigations

Calculate materials corrosion rates during an RBI review.

Assess possible causes of failure and compare expected and measured corrosion rates for operating conditions.

Education

Prepares refinery maintenance personnel for the API RP 571 endorsement test.

Provides information and calculators for less experienced personnel to perform more routine evaluations without the immediate help of a materials engineer.

Allows materials engineers to spend more time on solving more complex issues.

Educates users through repetition of use.

Transfers technology to the next generation.